Peaches

Recommended

Conventional cooling

Dynamic Cooling

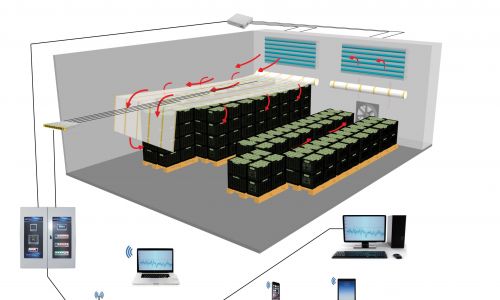

Pre-cooling

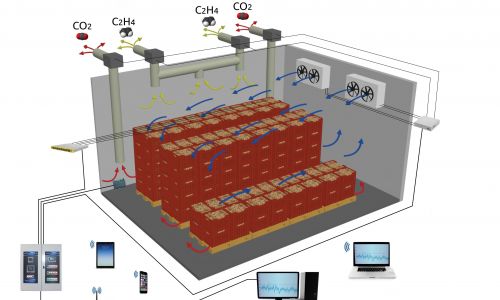

De-greening

Ripening

General Tips for Peaches

| Storage temperature | Relative Humidity (RH) | Duration | Pre-cooling | Sensitivity to ethylene | Ethylene Production | Controlled Atmosphere |

|---|---|---|---|---|---|---|

|

Storage temperature:

-0,2° - 0,2° C

|

Relative Humidity (RH):

85%-92%

|

Duration:

2-6 weeks

|

Pre-cooling:

Air cooling

|

Sensitivity to ethylene:

Moderate

|

Ethylene Production:

Very high

|

Controlled Atmosphere:

Recommended

|

Storage Temperature: Recommended storage temperature is −0.2 °C. |

High Humidity: Use an air-cooler with a low air–product temperature differential (ΔT). |

Storage Duration: Recommended period is 2 – 6 weeks. |

Ozone: Install an ozone-generation unit to ensure effective microbial control. |

Ethylene Removal: The use of an ethylene burner is recommended. |

Ventilation: A digitally controlled ventilation system should be installed for consistent air exchange. |

Air Circulation: Use inverter-driven fans with digital control to maintain uniform airflow throughout the chamber 24/7. |

Controlled Atmosphere: Recommended gas composition: 2 % – 5 % O₂ and 3 % – 6 % CO₂. Controlled Atmosphere delays ripening and maintains flesh firmness for up to 75 days. |

Dynamic Pre-Cooling: Detailed study of temperature absorption time and airspeed ensures uniform core-to-surface cooling across the entire load. |

Dynamic Cooling: Continuously monitors multiple control points and automatically adjusts environmental parameters across the entire chamber for optimal uniformity. |

- Rapid pre-cooling to 1 °C (core temperature) and maintenance of the cold chain throughout all distribution stages.

- Keep storage temperatures uniformly below zero within the chamber.

- Dynamic Cooling application is essential for high-quality preservation.

- Use low-velocity air movement to achieve gentle and even cooling.

- Maintain medium CO₂ levels to support quality retention — concentrations above 20 % cause off-flavors and surface browning.

- Remove ethylene continuously to prevent premature ripening.

- During harvest, firmness should exceed 3.5 kg force, measured with an 8 mm penetrometer tip.

- Sugar content at harvest should be below 9 °Brix, measured with optical refractometers.

- Disinfect cold-storage chambers before use.

- Avoid external odors, as peaches easily absorb environmental smells.