Dynamic Pre-Cooling

Dynamic Pre-Cooling

Dynamic Pre-Cooling is an advanced method for the rapid removal of field heat from fruits and vegetables.

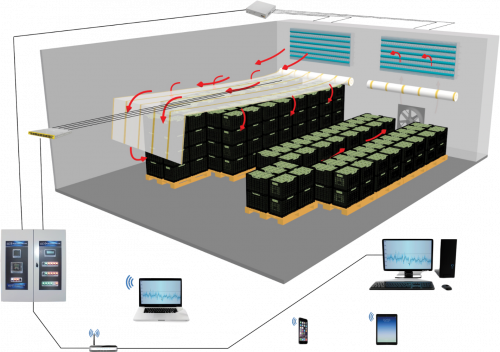

The system automatically adapts to the specific conditions of each load, ensuring maximum freshness, uniform temperature reduction, and optimized energy efficiency.

The process is based on the continuous monitoring and regulation of multiple parameters — including temperature, air velocity, air volume, and concentrations of ethylene (C₂H₄) and carbon dioxide (CO₂).

These parameters are controlled through a network of sensors installed in the Dynamic Pre-Cooling chambers. Certain sensors — such as core-penetration temperature probes — can be repositioned and inserted directly into the product mass to provide accurate core-temperature readings during the cooling process.

The Dynamic Pre-Cooling system employs high-suction mechanisms and adaptive control programs, allowing it to adjust automatically to different packaging configurations, including:

Suitable for field-harvested produce in perforated crates

Suitable for single/double-row cartons or open packaging

Suitable for small packs or flow-pack film packaging

Reduces pre-cooling time

Ensures uniform core temperature

Prevents temperature and gas fluctuations via preset programs and remote monitoring

Strawberry Dynamic Pre-Cooling – Indicative Table

| Harvest Temperature (°C) | Initial Cooling (hours) | Target Temperature for Flow-Pack (°C) | Final Pre-Cooling for Flow-Pack (hours) | Final Target Temperature (°C) |

| 5 | 10 | +3°C | +2h | +2°C |

| 7 | 9 | +4°C | +3h | +2°C |

| 10 | 8 | +5°C | +4h | +2°C |

| 15 | 7 | +5°C | +4h | +2°C |

| 20 | 6 | +6°C | +5h | +2°C |

| 25 | 4 | +7°C | +6h | +2°C |

| 30 | 3 | +7°C | +6h | +2°C |

| 35 | 2 | +7°C | +6h | +2°C |

| 40 | 1 | +7°C | +6h | +2°C |

Dynamic Pre-Cooling is an advanced thermal management process that rapidly removes field heat from produce through continuous, sensor-based control and adaptive regulation of key parameters.

The system ensures uniform temperature equalization, minimization of physiological and microbial deterioration, and maximum retention of product integrity from the initial stage of post-harvest handling.