Cherries

Recommended

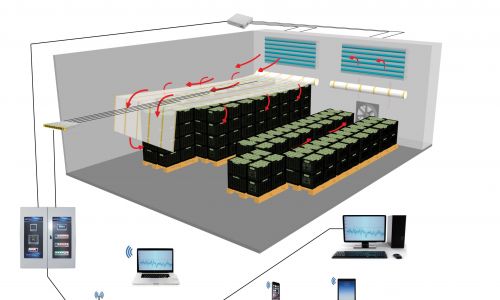

Conventional cooling

Dynamic Cooling

Pre-cooling

De-greening

Ripening

General Tips for Cherries

| Storage temperature | Relative Humidity (RH) | Duration | Pre-cooling | Sensitivity to ethylene | Ethylene Production | Controlled Atmosphere |

|---|---|---|---|---|---|---|

|

Storage temperature:

0° C

|

Relative Humidity (RH):

85%-90%

|

Duration:

10 – 30 days

|

Pre-cooling:

1.Hydro-cooling 2.Air-cooling

|

Sensitivity to ethylene:

Very low

|

Ethylene Production:

Very low

|

Controlled Atmosphere:

Not recommended

|

It is recommended to store at 0 °C. |

High humidity: Choose an air-cooler with a low air–product temperature differential (ΔT). |

A storage period of 10 to 30 days is advised. |

Controlled Atmosphere: Not recommended — uneconomical for small volumes and limited benefit relative to total storage time. |

Hydro-coolers are recommended immediately after harvest of cherries. |

Dynamic pre-cooling is advised for packaged cherries; a study must be done of absorption time and air velocity to ensure uniform cooling down to the core of the product. |

IMPORTANT TIPS

- Rapid pre-cooling and maintenance of the cold chain throughout all handling phases of the chilled product.

- Pre-cooling must take place within four hours of harvest.

- Use approved disinfectants in the hydro-cooler water during use.

- Maintain ambient temperature in sorting/packing area around 15 °C.

- Ensure uniform temperature inside cold-storage chambers.

- Cooling must be achieved by low-air-speed circulation.

- High CO₂ levels help good preservation (not above ~30 %).

- Monitor sugar level at harvest (14–16 ° Brix) using optical refractometers.

- Disinfect cold-storage chambers before use.

- Use modified-atmosphere bags for storage.