Dynamic De-Greening

Dynamic De-Greening

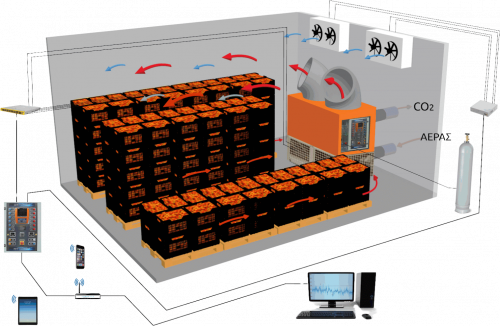

Dynamic De-Greening is a controlled-ripening method based on the continuous monitoring and regulation of multiple parameters — including temperature, humidity, and the concentrations of carbon dioxide (CO₂) and ethylene (C₂H₄) — through a network of specialized sensors.

A predefined sequence of automated control actions continuously adjusts the operating mechanisms that generate de-greening conditions, maintaining ideal parameters across the entire chamber volume at all times.

Ensures uniform, attractive coloration across every fruit and pallet

Monitors and regulates parameters in real time (temperature, humidity, ethylene, CO₂) for safe and predictable outcomes

Provides remote control and automated alerts in case of faults or parameter deviations

Dynamic De-greening Indicative Table

| Product | Recommended Temperature (°C) |

|

Oranges (Early)

|

20-22° |

|

Oranges (Late)

|

22-24° |

|

Lemos

|

23-25° |

|

Grapefruit

|

24-26° |

|

Peppers

|

23-25° |

| Mandarins (Sensitive) | 18-19° |

|

Mandarins (Resistant)

|

21-22° |

|

Kumquat

|

18-20° |

Dynamic De-Greening is an advanced automated process that continuously regulates chamber conditions in real time, ensuring uniform color development, controlled ethylene application, and optimal fruit quality with reduced costs and minimal losses.