Portable Dynamic De-Greening Unit

Creates ideal de-greening conditions in any cold storage chamber

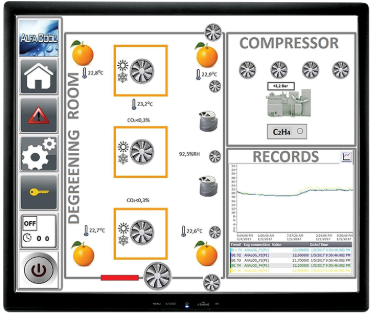

Continuous Temperature Monitoring

Real-time control of thermal conditions throughout the chamber.

Automatic Regulation of Parameters

Maintains stable environmental conditions through adaptive automation.

Dynamic Adjustment of Control Mechanisms

System components respond instantly to feedback from multiple sensors.

Easy Transport and Storage

Lightweight design enables flexible relocation between facilities.

Technical Specifications

Technical Overview

The Portable Dynamic De-Greening Unit provides continuous multi-point monitoring across the product mass, ensuring uniform color development and surface protection.

It integrates automated control of ethylene (C₂H₄) and carbon dioxide (CO₂) levels — performing scheduled ventilation cycles to maintain optimal gas concentrations.

Temperature and humidity are precisely regulated, and data are managed through a PLC interface (shown right: orange de-greening control screen).

Results

● Uniform product coloration

● Prevention of dehydration on fruit surfaces

● Protection against surface burns

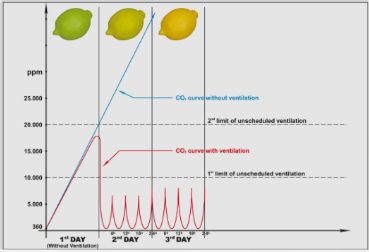

(Left: lemon de-greening process diagram)

Dynamic De-Greening is an advanced automated process that continuously regulates chamber conditions in real time, ensuring uniform color development, controlled ethylene application, and optimal fruit quality with reduced costs and minimal losses.