Oranges

Recommended

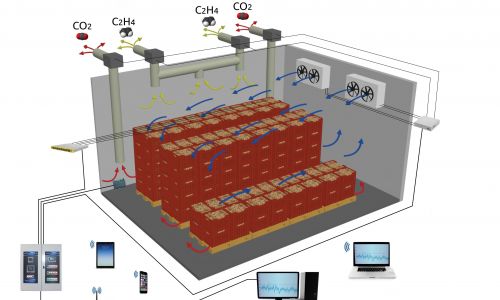

Conventional cooling

Dynamic Cooling

Pre-cooling

De-greening

Ripening

General Tips for Oranges

| Storage temperature | Relative Humidity (RH) | Duration | Pre-cooling | Sensitivity to ethylene | Ethylene Production | Controlled Atmosphere |

|---|---|---|---|---|---|---|

|

Storage temperature:

2° - 4° C

|

Relative Humidity (RH):

88%-92%

|

Duration:

2 - 4 months

|

Pre-cooling:

Not required

|

Sensitivity to ethylene:

Very low

|

Ethylene Production:

Very low

|

Controlled Atmosphere:

Not recommended

|

Storage Temperature: Recommended range is 2 °C – 4 °C. |

High Humidity: Use an air-cooler with a low air–product temperature differential (ΔT). |

De-greening: Process only the required fruit quantity according to the capacity of the ripening room. |

Storage Duration: Recommended period is 2 - 4 months |

Ventilation: Install a digitally controlled ventilation system for precise air exchange management. |

Controlled Atmosphere: Not recommended — uneconomical for small-scale production, offering limited advantages in total storage duration. |

IMPORTANT TIPS

- Avoid temperatures below the recommended range, as these cause peel injury and surface burns.

- For post-harvest pest control, apply cold treatment at 2 °C for 24 hours after first raising fruit sugar content by keeping them at 15 °C for one week.

- Maintain low CO₂ levels, which help preserve fruit quality.

- De-green oranges using 1–10 ppm ethylene at 22 °C – 24 °C, 90 % – 95 % RH, for 2–3 days.

- Monitor sugar content at harvest using optical refractometers — optimal range is 8.5 °Brix – 9 °Brix.

- Disinfect cold-storage chambers before use.

- Check juice content before harvest — minimum 40 % is recommended.

- Disinfect and wax fruit before storage to extend shelf life and maintain appearance.