Avocados

Recommended

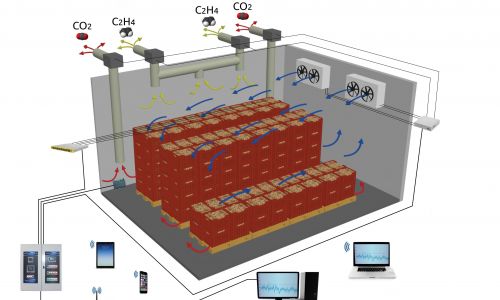

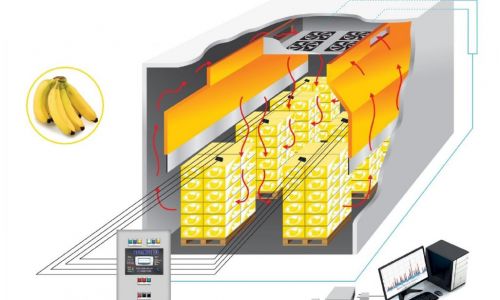

Conventional cooling

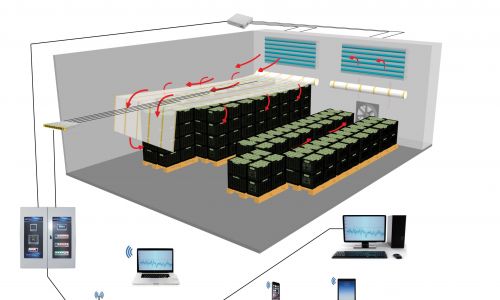

Dynamic Cooling

Pre-cooling

De-greening

Ripening

General Tips for Avocados

| Storage temperature | Relative Humidity (RH) | Duration | Pre-cooling | Sensitivity to ethylene | Ethylene Production | Controlled Atmosphere |

|---|---|---|---|---|---|---|

|

Storage temperature:

5 έως 8°C

|

Relative Humidity (RH):

90%-95%

|

Duration:

4 – 6 weeks

|

Pre-cooling:

Forced-air cooling

|

Sensitivity to ethylene:

High

|

Ethylene Production:

Very high

|

Controlled Atmosphere:

Not recommended

|

Storage Temperature: Maintain at 5 – 8 °C. |

High Humidity: Install humidifiers capable of reaching the upper RH range, or choose forced-air cooling systems operating with a minimal air–product temperature differential (ΔT). |

Storage Duration: Recommended 4 to 6 weeks. |

Ethylene Removal: Use an ethylene burner or an ethylene absorption unit, as avocados are highly sensitive to trace ethylene. |

Controlled Atmosphere: Not recommended for small-scale production—limited benefit relative to cost. |

Ozone Application: Recommended installation of ozone generator to reduce microbial load. |

Ventilation & Air Exchange: Digital-controlled ventilation mechanism is advised for the chamber. |

Pre-Cooling: Conduct a specialized study of absorption time and air velocity to ensure uniform cooling, reaching the core of the product. |

-

Conduct rapid pre-cooling after harvest and before commercial dispatch.

- Maintain the cold chain at all stages of handling and distribution.

- Remove ethylene exposure — avocados exhibit high sensitivity to trace ethylene.

- For ripe avocados: A treatment of 10 ppm ethylene at 20 °C can ripen fruit in 48 hours.

- Sanitize cold-rooms before use to control microbial load.

- CO₂ management: Keeping CO₂ at low levels supports better retention, but levels above ~10% may deteriorate flavour.