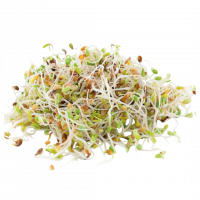

Sprouts

Recommended

Conventional cooling

Dynamic Cooling

Pre-cooling

De-greening

Ripening

General Tips for Sprouts

| Storage temperature | Relative Humidity (RH) | Duration | Pre-cooling | Sensitivity to ethylene | Ethylene Production | Controlled Atmosphere |

|---|---|---|---|---|---|---|

|

Storage temperature:

0° C

|

Relative Humidity (RH):

94%-96%

|

Duration:

5-10 days

|

Pre-cooling:

Not required

|

Sensitivity to ethylene:

Low

|

Ethylene Production:

Medium

|

Controlled Atmosphere:

Not recommended

|

Artificial Production: Sprouts are cultivated under controlled conditions in dedicated production lines. These facilities must maintain strict hygiene protocols, including frequent washing and disinfection with approved, low-residue sanitizing agents to prevent contamination by fungi and bacteria. |

Low-Airflow Continuous Water Circulation Chambers: Designed for products requiring high humidity, maintaining less than 25 air recirculations per hour relative to chamber volume. High humidity is ensured through continuous water flow, preventing dehydration. |

Ozone Systems: The installation of ozone generators is recommended to minimize microbial load and maintain a hygienic storage environment. |

IMPORTANT TIPS

- Always store sprouts at the recommended temperature (0°C).

- Thoroughly wash production facilities with chlorinated, ozonated, or other approved disinfected water to prevent spoilage and bacterial contamination.

- High levels of CO₂ contribute to longer shelf life and slower deterioration.

- Use ozone systems to control fungal growth.

- Use Modified Atmosphere Packaging (MAP) to maintain freshness.

- Store sprouts in well-ventilated packaging that allows air to pass through for effective cooling.

- Remove ethylene using ventilation or absorbers to maintain product integrity.