Tomatoes

Recommended

Conventional cooling

Dynamic Cooling

Pre-cooling

De-greening

Ripening

General Tips for Tomatoes

| Storage temperature | Relative Humidity (RH) | Duration | Pre-cooling | Sensitivity to ethylene | Ethylene Production | Controlled Atmosphere |

|---|---|---|---|---|---|---|

|

Storage temperature:

12° – 14° C

|

Relative Humidity (RH):

85%

|

Duration:

2-4 weeks

|

Pre-cooling:

Air cooling

|

Sensitivity to ethylene:

High

|

Ethylene Production:

Medium

|

Controlled Atmosphere:

Not recommended

|

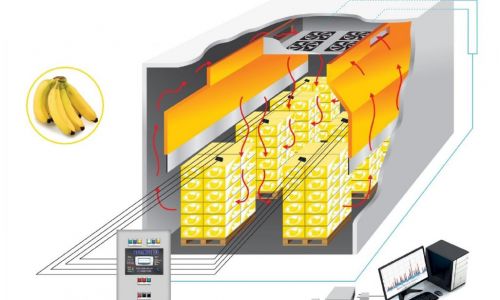

Dynamic Pre-Cooling (High-Suction Capacity Units): Specialized study of heat absorption time and airflow velocity ensures uniform temperature reduction throughout the product mass. Used for both packed and unpacked tomatoes, pre-cooling delays ripening and significantly extends shelf life. |

Pallet Arrangement: To ensure uniform temperature during storage, maintain 5–10 cm gaps between pallets, aligned with the airflow direction of cold air circulation. |

IMPORTANT TIPS

- Rapid pre-cooling at 14°C in Dynamic Pre-Cooling Units, followed by continuous cold chain maintenance across all stages of handling and transport.

- Dynamic Cooling is essential for optimal preservation and extended storage duration.

- Do not store tomatoes alongside ethylene-producing fruits such as apples, pears, peaches, or nectarines.

- Avoid temperatures below 8°C, as chilling injury may occur — leading to surface pitting, poor color development, and internal breakdown.

- Degreen in Dynamic Degreening Chambers, applying ethylene to maintain a steady concentration of 100–150 ppm throughout the process.

- Control CO₂ levels to prolong storage life and preserve quality attributes.

- Store tomatoes at the lower threshold of physiological ripeness (third green stage) before degreening for optimal post-harvest performance.