Dry Onions

Recommended

Conventional cooling

Dynamic Cooling

Pre-cooling

De-greening

Ripening

General Tips for Dry Onions

| Storage temperature | Relative Humidity (RH) | Duration | Pre-cooling | Sensitivity to ethylene | Ethylene Production | Controlled Atmosphere |

|---|---|---|---|---|---|---|

|

Storage temperature:

-0,2° to 0,5° C

|

Relative Humidity (RH):

72%-76%

|

Duration:

8-10 months

|

Pre-cooling:

Not required

|

Sensitivity to ethylene:

Low

|

Ethylene Production:

Very low

|

Controlled Atmosphere:

Not recommended

|

Dynamic Surface Drying (Essential): Before long-term storage, onions must be thoroughly dried in specialized cold rooms equipped with ventilation ducts and air-control systems. |

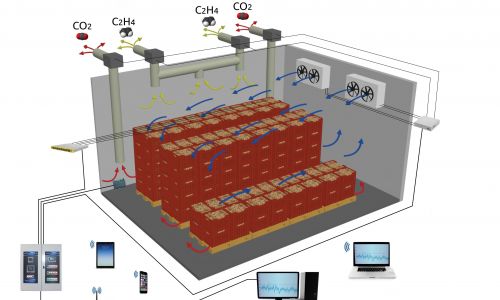

Dynamic Cooling: Monitors and regulates all critical storage parameters at multiple points throughout the chamber 24/7, extending storage life by 15%–20% beyond conventional systems. |

IMPORTANT TIPS

- Dynamic Cooling is essential for preserving onion quality during long-term storage.

- Avoid prolonged high temperatures during the pre-storage drying phase.

- Do not store onions that were exposed to excessive humidity during cultivation.

- Controlled drying can be performed directly inside the cold room by adjusting ventilation and humidity levels.

- Delay the temperature drop below 10°C at the start of storage to promote the formation of additional protective skins.

- Maintain drying conditions at 18°–25°C and 40% RH during the first five days after loading the cold chamber.

- Use low-humidity refrigeration systems.

- Remove ethylene via specialized ventilation systems.

- Maintain moderate CO₂ levels to prevent spoilage and preserve onion quality.

- Ensure continuous air recirculation within the chamber using independent fans, operating 24 hours a day.