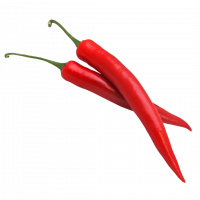

Hot Peppers

Recommended

Conventional cooling

Dynamic Cooling

Pre-cooling

De-greening

Ripening

General Tips for Hot Peppers

| Storage temperature | Relative Humidity (RH) | Duration | Pre-cooling | Sensitivity to ethylene | Ethylene Production | Controlled Atmosphere |

|---|---|---|---|---|---|---|

|

Storage temperature:

7,5° C

|

Relative Humidity (RH):

>95%

|

Duration:

3-5 weeks

|

Pre-cooling:

Air cooling

|

Sensitivity to ethylene:

High

|

Ethylene Production:

Very low

|

Controlled Atmosphere:

Not recommended

|

Dynamic Pre-Cooling (High-Suction Capacity Chambers): Specialized design ensuring uniform temperature absorption and air velocity throughout the product mass, suitable for both packaged and unpackaged produce. |

Dynamic Cooling: Continuously regulates critical parameters throughout the chamber, maintaining stable conditions 24/7. Extends storage life by 15–20% beyond standard data values. |

Enhanced Cold Room: Flexible solution that allows existing refrigeration chambers and systems to perform light pre-cooling before switching to storage operation. |

Modified Atmosphere Packaging (MAP): Use of specialized MAP bags is recommended to extend storage duration and preserve product firmness, color, and flavor. |

IMPORTANT TIPS

- Dynamic Cooling is essential for maintaining product quality and freshness.

- Conduct rapid pre-cooling in Dynamic Pre-Cooling Units and maintain a continuous cold chain throughout handling and transport.

- Pre-cool in an Enhanced Cold Room, then store under stable conditions to prevent quality loss and fungal development.

- Do not store below 7°C — low temperatures cause chilling injuries and internal darkening.

- Remove ethylene using ventilation or absorbers to slow down softening.

- Install ozone generators to suppress fungal growth and microbial activity.

- Monitor CO₂ levels to prevent physiological damage and maintain optimal firmness.